Your one-stop shop to harden any space.

Services

/01

Threat Assessment & Project Planning

/02

Production

/03

Installation

Factory

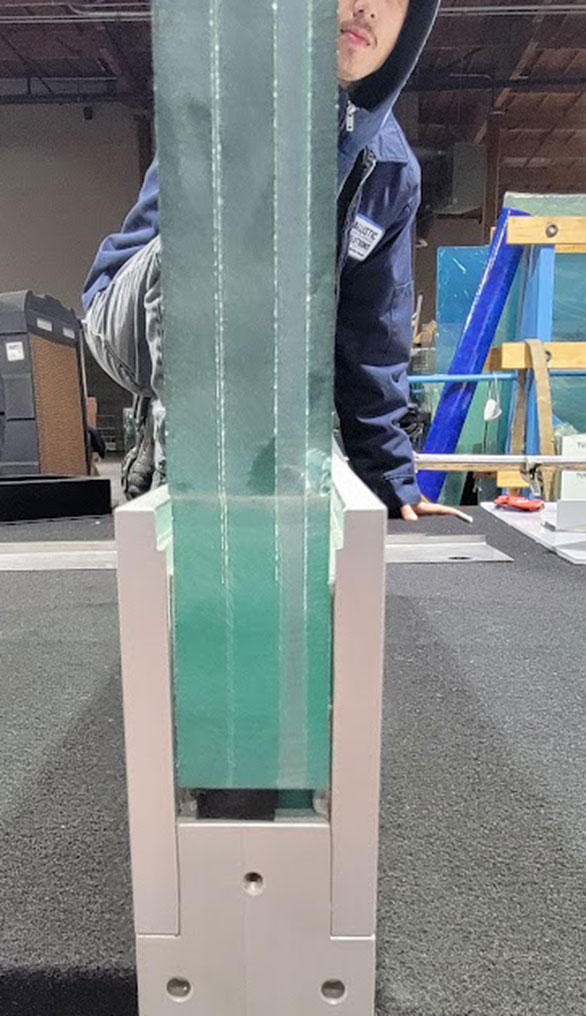

We manufacture everything we sell in our Addison, Texas factory. This full-service facility allows us to produce custom jobs with industry-leading speed and quality.

Best-in-Class Schedule Accuracy & Turnaround

Our factory operates two eight-hour shifts, with a custom scheduling system that manages resources down to the minute. This allows us to provide incredibly accurate scheduling and best-in-class lead times for our customers.

Industry-Leading Quality

We’re able to stand confidently behind our work thanks to our strict material standards, precise manufacturing equipment, skilled and stable workforce, and redundant quality assurance practices.

Each piece of glass we ship undergoes multiple inspections, ensuring that it meets our stringent standards for everything from flatness to reflected distortion. Plus, our custom-designed packaging includes “tip-n-tell” tags and G-force shock indicators that detect tip-overs and drops during transit, to ensure your product’s quality even after it leaves our facility.

Everything Under One Roof

We have the in-house capabilities to produce complex and customized products, so when you buy from Ballistic Glass & Armor Solutions you can rest assured that your entire job will be produced following our tightly-controlled production and quality assurance processes.

- CNC glass and polycarbonate cutting up to 96x130”

- Industry-leading material optimization software to maximize yield on custom-size orders

- Automated edge deletion for Low-E glass

- Edge seaming and arrising

- Climate-controlled clean room for stacking and bagging

- Custom construction of high-temperature vacuum bags for each assembly

- Electric convection chiller-cooled autoclave: Max size unit 60” x 120”

- NASA gas-fired evaporative cooling autoclave: Max size unit 70” x 130”

- 50hp variable pressure pump waterjet

- CNC capability to cut any shape or size

- Custom cut-outs up to roughly 6’ by 13’ and 7” thick

- Accurate to .005”/3 ft

- Custom fabrication of steel and aluminum door, window, and storefront framing

- Assembly of custom steel and aluminum single and double doors

- Assembly of custom steel and aluminum window and storefront framing

- Assembly of custom ballistic partition frames

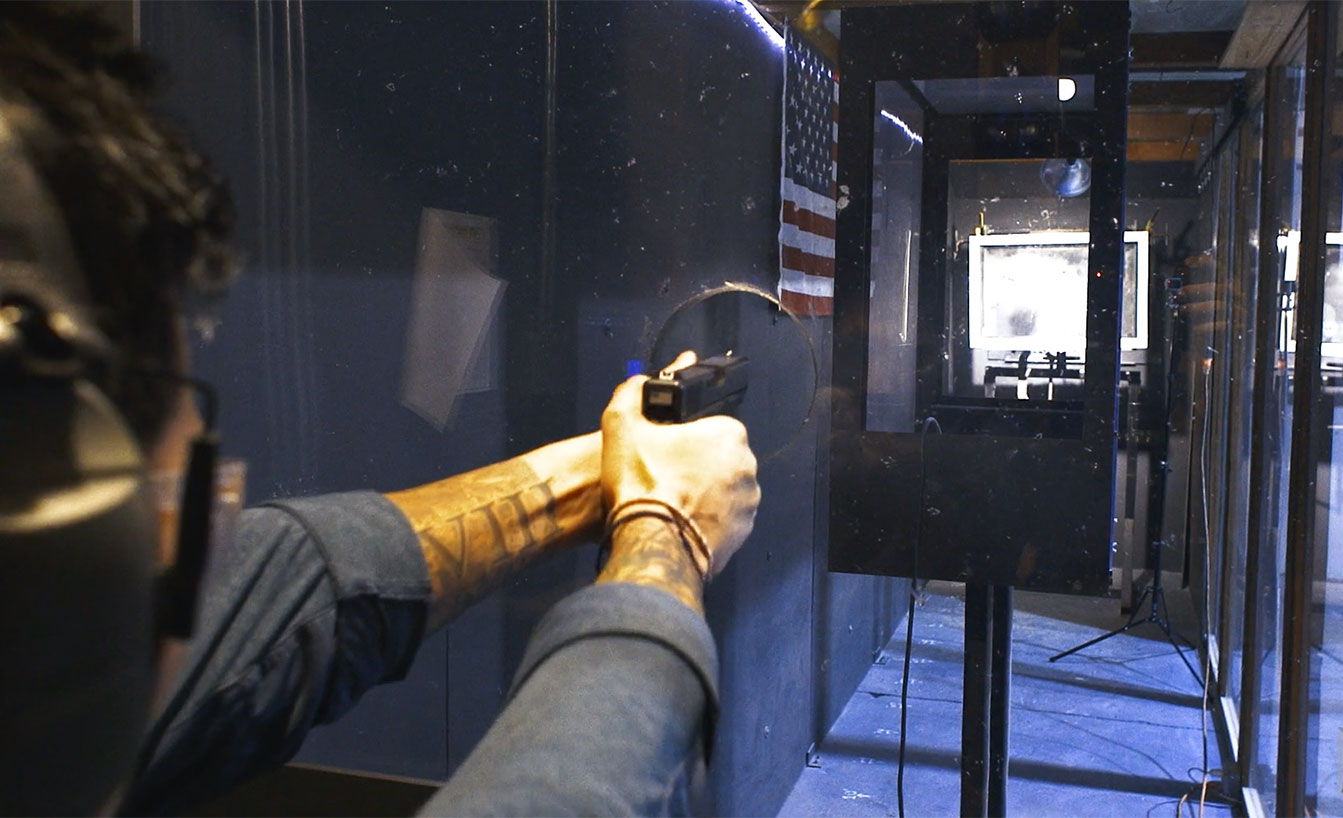

Testing

Every Ballistic Glass & Armor product is independently tested against the ballistic penetration limits included in the United States Underwriters Laboratory (UL) standard commonly known as UL 752, which establishes 10 levels of resistance to ballistic threats from a 9 mm handgun (Level 1) to a military-grade .50 caliber rifle (Level 10). Learn more about UL 752 ratings on our Resources page.

Additionally, products like our SchoolSafe™ solutions are put through market-specific tests to ensure that they meet or exceed standards, such as the ASTM F3561 standard test method for forced-entry-resistance of fenestration systems after simulated active shooter attack.

We provide product-specific testing standards on our product specification sheets, with more information about testing standards available on our Resources page.

Let’s find your solution